Many of the most interesting products I’ve worked on have resulted from the efforts of dozens or even hundreds of people, each an expert in their field, and each creative in their own way. I’m talking about systems with dozens or hundreds of parts, stringent performance requirements, and severe constraints. Typically the team is inventing the technology in parallel to doing user research and initial design and engineering. On the best projects, everyone has due diligence to do so that as we move through the process the transitions from idea to proof-of-concept to design to product are as seamless as possible.

To get to work on complex system design, you need to tackle complex problems; it helps of the environment in which these products must function is demanding, and of course, if human performance is also limited in some way. No surprise then that designing space hardware is a lot of fun.

To get to work on complex system design, you need to tackle complex problems; it helps of the environment in which these products must function is demanding, and of course, if human performance is also limited in some way. No surprise then that designing space hardware is a lot of fun.

One of the first projects I had the opportunity to take a lead role on was developing a Time-of-Flight Mass Spectrometer for Space Station Freedom (later to be absorbed the International Space Station Program). I was young (and cheap) and ready for a challenge. Industrial Designer wasn’t an officially recognized contractor designation, so I got bumped to Systems Integration Manager. I’m pretty sure nobody above me had a clear idea what my role was to be, but it was one crazy roller-coaster ride.

A mass spectrometer is used to determine the make-up of a chemical sample; most people have seen them used at airports being used to detect explosives. Our task was to develop a pistol-like hand-held device the shuttle crewmembers could use during EVA (Extra-vehicular activity) as they assembled the International Space Station. The goal was to be able to check the integrity of couplings & to detect toxic chemicals which could prove harmful or fatal if brought back into the crew compartments.

ID as Sheepdog. On this project we had chemists, electrical, mechanical and thermal engineers, managers, senior managers, super senior managers, client liaisons… the list goes on and on. Part of every day involved spending time with each development team, understanding where they were at, where their research was leading them, what their requirements were, how that would impact the overall design, and brainstorming workarounds to make sure that nobody painted anyone else into a corner. Meanwhile, I also was responsible for human factors and doing my own exploration into mobility, reach envelopes, NASA standards, and how to create a truly usable system.

A picture is worth a thousand words. The second half of my role involved creating the packaging concept (and use model) for the device itself. As the development progressed, each team had a series of choices to make (often with multiple concepts that were equally acceptable to them). One of my projects was to create a packaging underlay of all the systems, and spend some effort focusing on how they all were coming together to stave of problems down the line.

A picture is worth a thousand words. The second half of my role involved creating the packaging concept (and use model) for the device itself. As the development progressed, each team had a series of choices to make (often with multiple concepts that were equally acceptable to them). One of my projects was to create a packaging underlay of all the systems, and spend some effort focusing on how they all were coming together to stave of problems down the line.

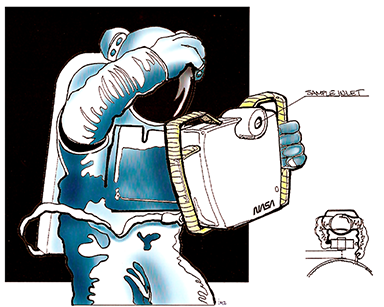

Pistol vs. Plate. Pretty quickly it became clear the pistol concept wasn’t going to work. Given how crewmembers translate and stabilize themselves in space and how long the device was, the front of a pistol concept would continuously be banging into the surfaces the crewmembers were trying to sample. If there was a leak, the sample inlet of the device would be flooded, making any nuanced measurements impossible. Our solution was to reorient the drift tube 90° and build a flat package which would fit between a crewmember and whatever they were working on. Problem solved, right?

The Grumpy General. Design reviews are a big deal on government projects; anywhere from a few dozen to close to a hundred people could be involved. Everyone from the NASA team, the prime contractor, the sub-contractor, visiting reviewers from sister NASA facilities, principal investigators… you get the idea. So I’m presenting the Plate packaging concept, walking through the components, layout, etc. and this general straight out of a movie starts getting restless. It’s distracting, but I keep going.

Finally he stops me and expresses his displeasure and says, “I was hoping for something a little more Buck Rogers…” Gulp. I walk him through the use mode, why we’ve designed it the way we did, and how this was a logical direction forward. He wasn’t convinced.

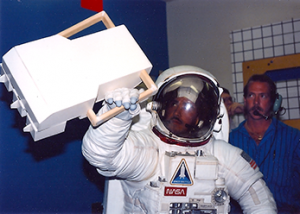

The Happy Astronauts. Fast forward a few months and I’m in Houston at Johnson Space Center evaluating form factor models with the team. We’ve got a crewmember in their EVA suit and we’re looking at usability, reach, and interface design preparing for WETF testing. As we wrap up our day, the astronaut says he wants to take me by the crew office so everyone can see what we’re working on. I ended up giving an impromptu demo to four or five crewmembers that happened to be in, and they seem pretty stoked. One of the big guns seems reluctant to return my model to me. Finally, as he’s handing it back to me he says:

The Happy Astronauts. Fast forward a few months and I’m in Houston at Johnson Space Center evaluating form factor models with the team. We’ve got a crewmember in their EVA suit and we’re looking at usability, reach, and interface design preparing for WETF testing. As we wrap up our day, the astronaut says he wants to take me by the crew office so everyone can see what we’re working on. I ended up giving an impromptu demo to four or five crewmembers that happened to be in, and they seem pretty stoked. One of the big guns seems reluctant to return my model to me. Finally, as he’s handing it back to me he says:

“That’s great. It’s about time someone designed this stuff for us!” –Story Musgrave.

Moral of the story: keep open to the possibility that your preconception of the ultimate solution might benefit from some up front research.